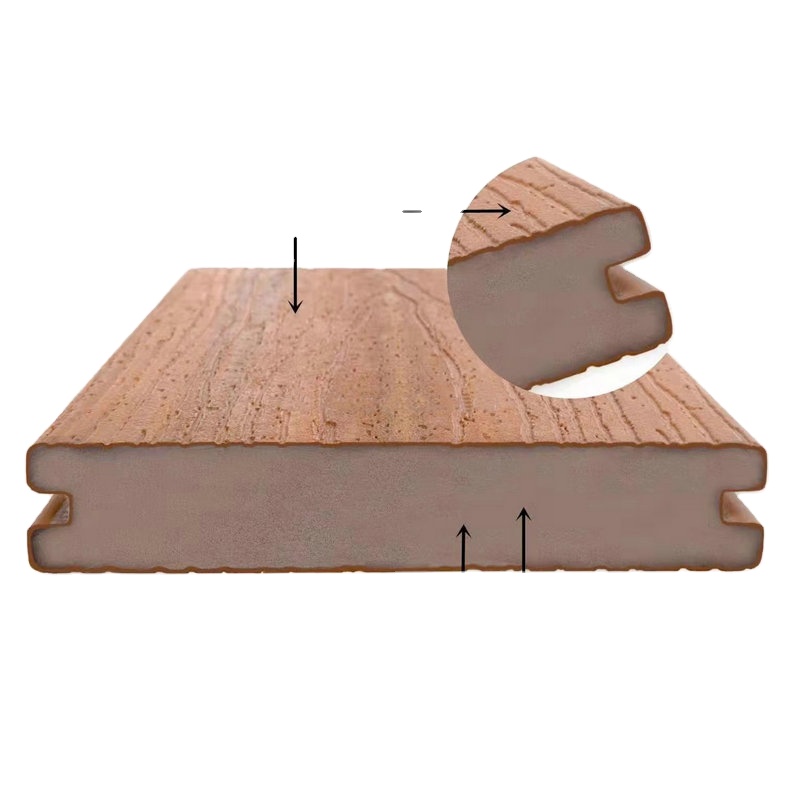

Custom Plastic Extrusion mold decorative Sheet Molding Product Parts Width Door Plank Sheet Mould

Custom Plastic Extrusion mold decorative Sheet Molding Product Parts Width Door Plank Sheet Mould

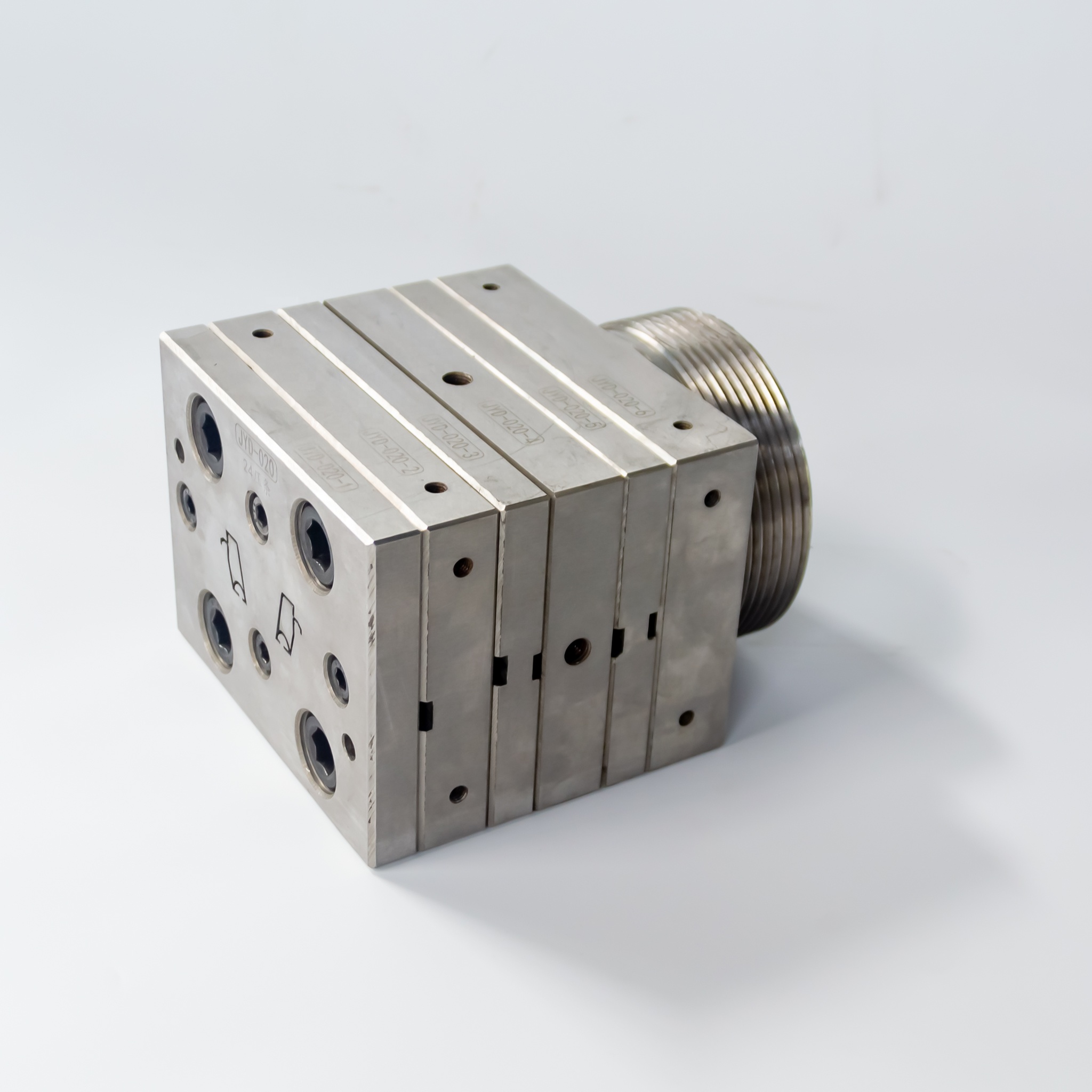

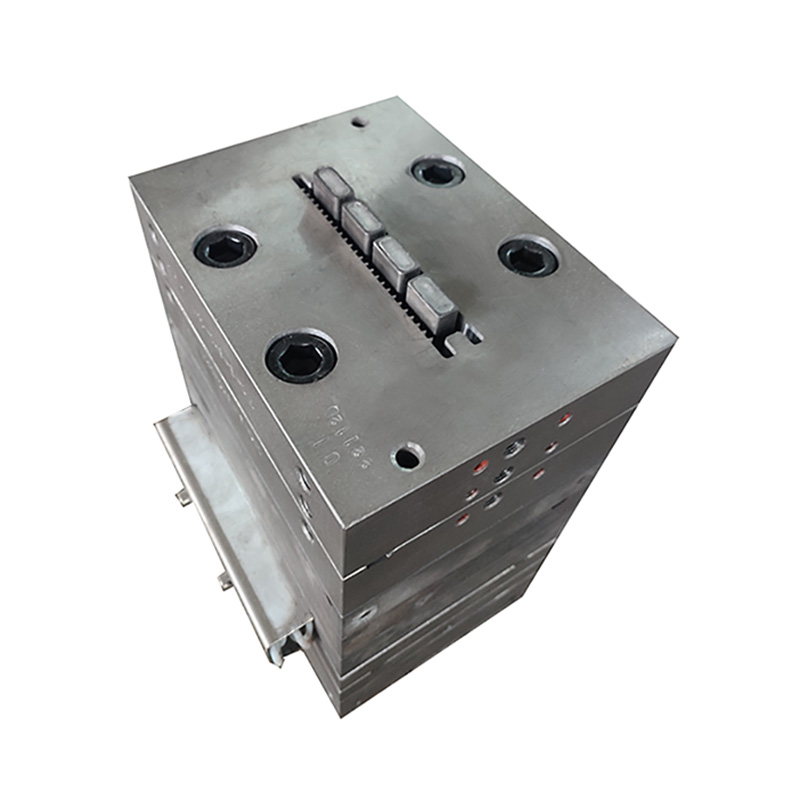

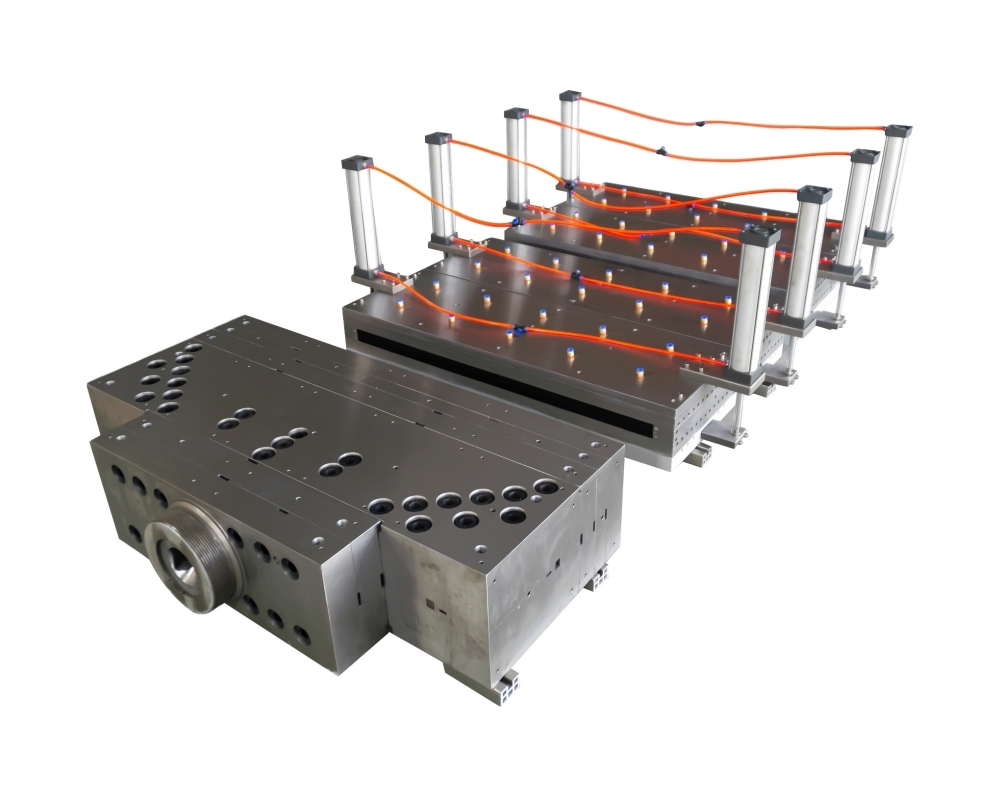

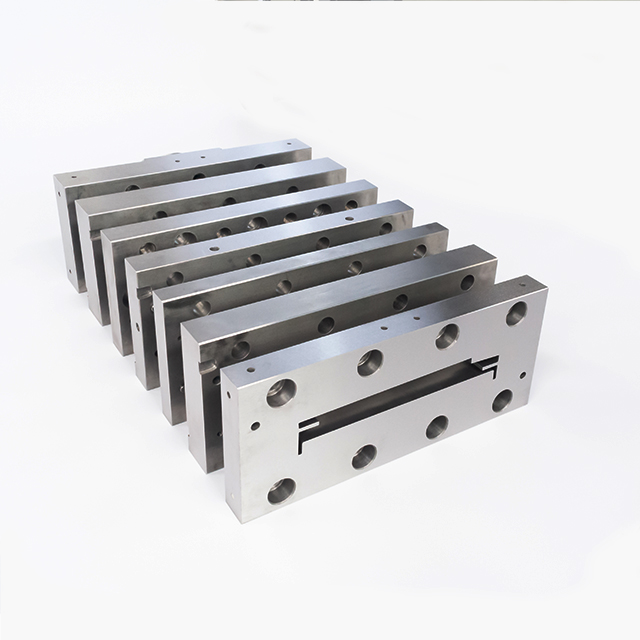

plastic extrusion mould

Mould Name | extrusion mould |

Mould cavity | 1 or multi-cavity |

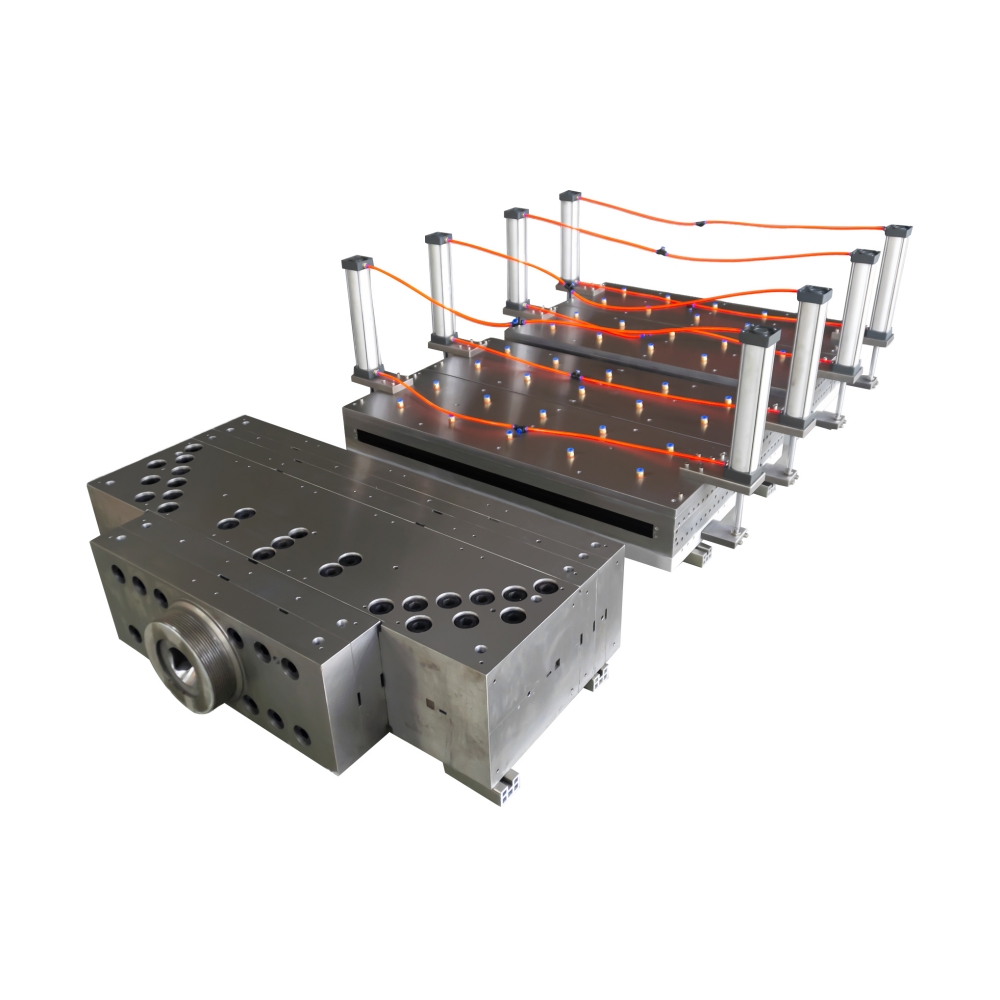

Mould composition | Die head, aluminum heating bands, calibrators and water tank |

Features | Selectable co-extrusion of different raw materials: PVC WPC |

Selectable technology | low-foaming, high-foaming & substance co-extrusion |

Stable | discharging, high efficiency, superior quality |

Test | Mould will be tested to get the satisfied sample before delivery Service |

Lead time | 30-40 days |

Application | Architecture decorative panel; wall panel;Shutter; landscape construction |

Extrusion mould material | 3Cr13,3Cr17,din1.2316 stainless steel |

size | 400-1200mm/Support customization |

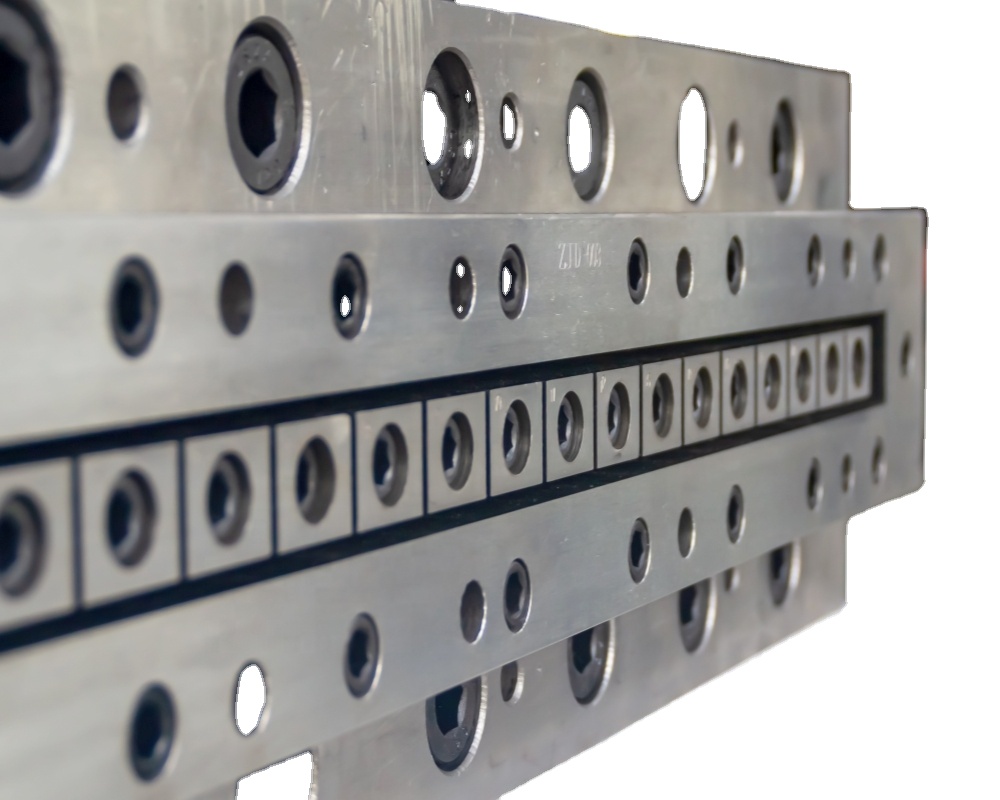

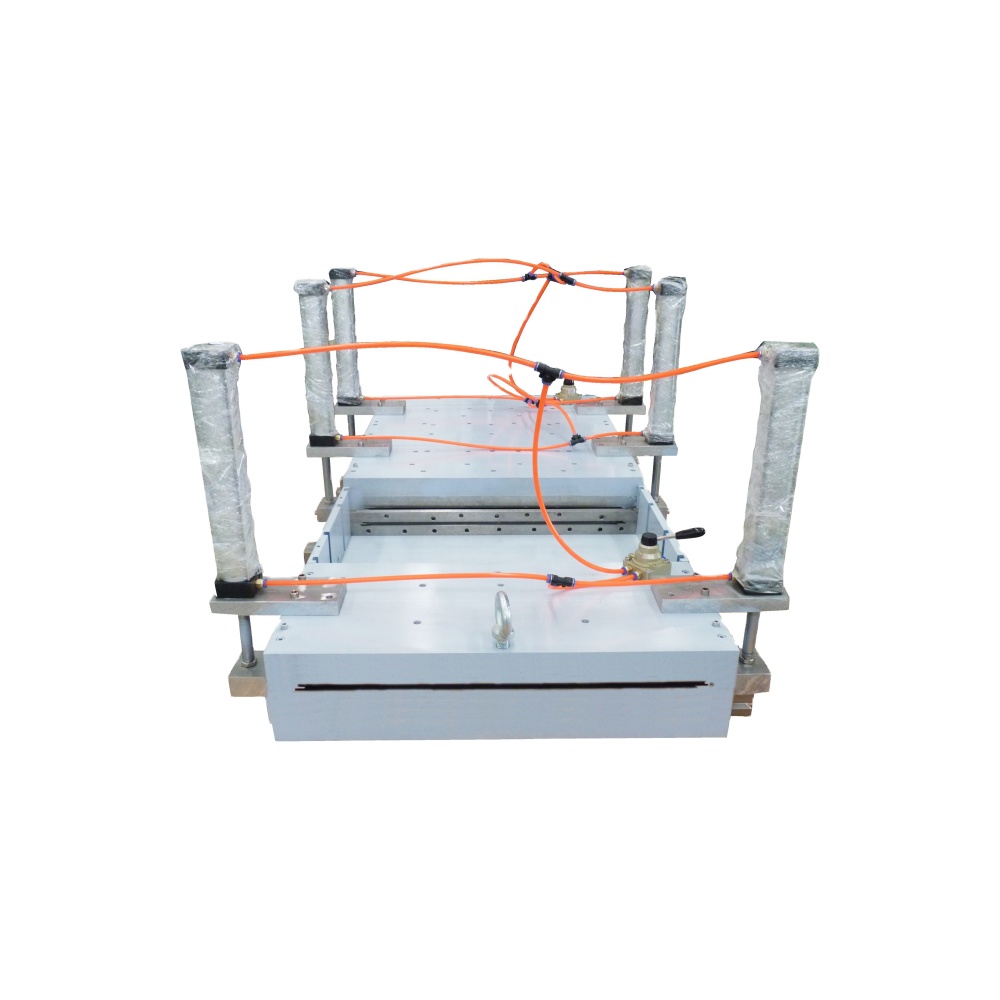

Calibrator

Length

800mm x 2

Height adjustment

Air/Oil - cylinder

Cooling

Transverse circulating water cooling

Vacuum

Vacuum chamber formed by upper and lower boards

Screw

Stainless steel screw

800mm x 2

Height adjustment

Air/Oil - cylinder

Cooling

Transverse circulating water cooling

Vacuum

Vacuum chamber formed by upper and lower boards

Screw

Stainless steel screw

Water tank

Length

2000mm x 1

Cooling

Water cooling

Vacuum

Vacuum is formed by pumping

Screw

Stainless steel screw

2000mm x 1

Cooling

Water cooling

Vacuum

Vacuum is formed by pumping

Screw

Stainless steel screw

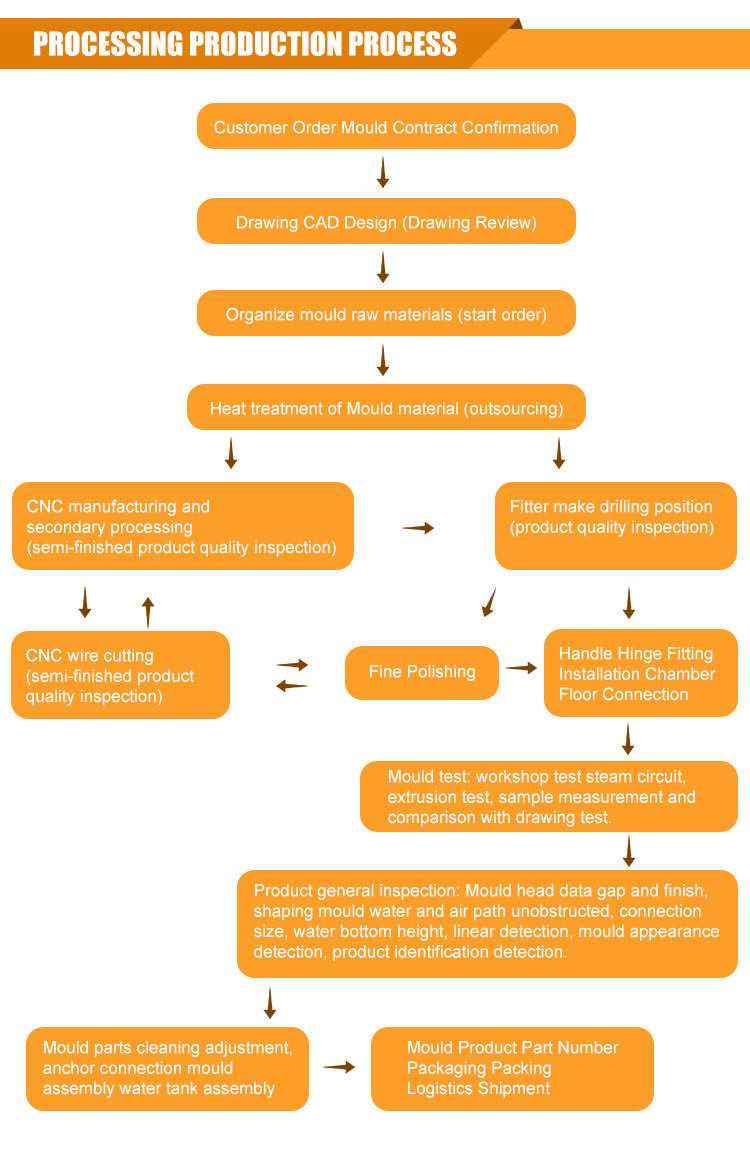

Q1: How long does it take to build an extrusion mold?

A: In general, it will take 4-5 weeks, depending on the complexity and cavity Number of the mold.

Q2: How do you provide after-sales service?

A:We provide after-sales service within one years after customer receive the mold. If the service area is in civil china, the cost is free.

Q3: Do you provide product assembly service?

A: we can provide production run and assembly service.

Q4: What is your payment term?

A: T/T is workable to you, normal we accept T/T Min 30% with order, and the balance before the shipment.

Q5:What is your business scope?

A:Our business scope is plastic mould,plastic extrusion product,plastic machine,etc, we can provide one-stop service.

Q6: How can I know the completion of my order?

A: Upon receipt of the deposit, we will immediately arrange for the production, after the order is completed, we will inspect and test all products carefully to ensure no damage and lost, we will also send you the detection images of your order before delivery for you,etc.

Q7: Can you guarantee your products?

A: Yes, base on our order and contract detail,we guarantee your 100% satisfaction on all our products.

A: In general, it will take 4-5 weeks, depending on the complexity and cavity Number of the mold.

Q2: How do you provide after-sales service?

A:We provide after-sales service within one years after customer receive the mold. If the service area is in civil china, the cost is free.

Q3: Do you provide product assembly service?

A: we can provide production run and assembly service.

Q4: What is your payment term?

A: T/T is workable to you, normal we accept T/T Min 30% with order, and the balance before the shipment.

Q5:What is your business scope?

A:Our business scope is plastic mould,plastic extrusion product,plastic machine,etc, we can provide one-stop service.

Q6: How can I know the completion of my order?

A: Upon receipt of the deposit, we will immediately arrange for the production, after the order is completed, we will inspect and test all products carefully to ensure no damage and lost, we will also send you the detection images of your order before delivery for you,etc.

Q7: Can you guarantee your products?

A: Yes, base on our order and contract detail,we guarantee your 100% satisfaction on all our products.

Product Tag: