JINTU MOULD: Custom WPC Molds

In the rapidly evolving world of composite materials, JINTU MOULD has established itself as a trailblazer among decking extrusion mold manufacturers in China, specializing in the design and production of high-precision hollow decking extrusion molds and WPC hollow board extrusion molds. With a focus on innovation, durability, and customization, JINTU MOULD empowers businesses to create superior wood-plastic composite (WPC) products that meet the demands of modern construction and outdoor living spaces.

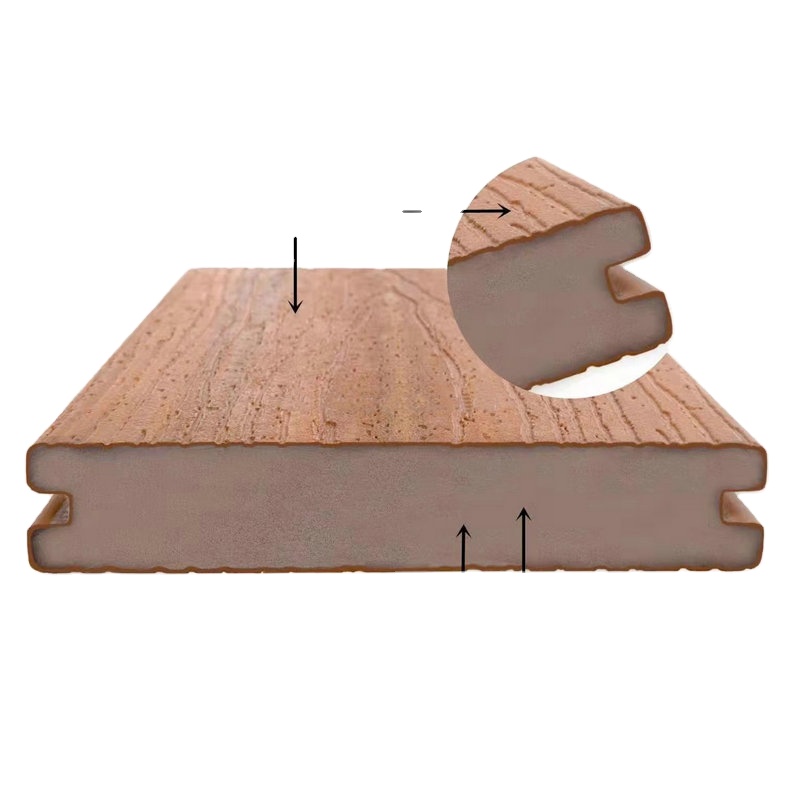

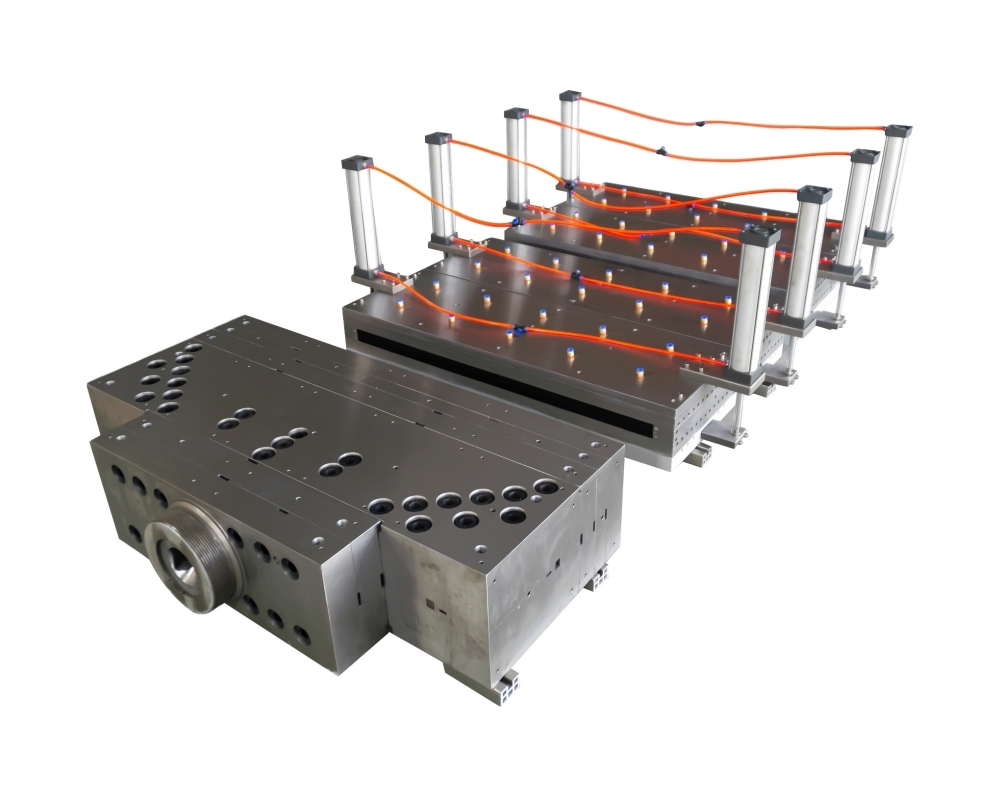

At the heart of JINTU MOULD’s expertise lies its mastery of WPC extrusion technology. The brand’s hollow decking extrusion molds are engineered to produce lightweight yet robust decking boards with hollow chambers, a design that enhances strength-to-weight ratios, improves thermal insulation, and reduces material costs. These molds are ideal for manufacturing decking used in residential gardens, commercial walkways, and marine applications, where durability and aesthetics are paramount.

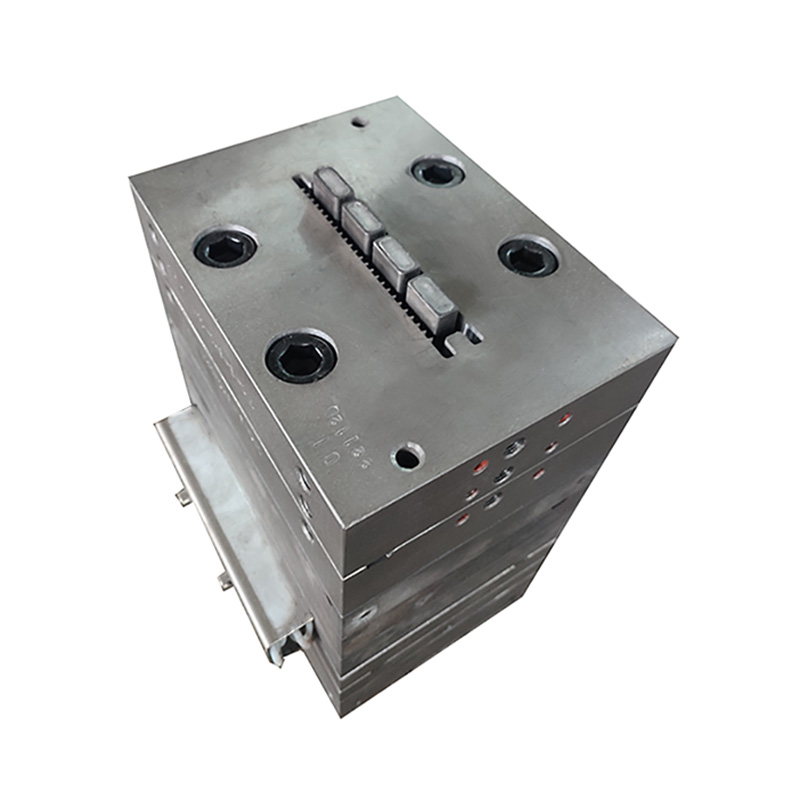

What sets JINTU MOULD apart is its reputation as a custom WPC extrusion mold supplier. Recognizing that every client has unique specifications—whether it’s board dimensions, hollow patterns, or surface textures—JINTU MOULD collaborates closely with businesses to develop tailored solutions. The brand’s in-house design team leverages advanced CAD/CAM software to create molds that align perfectly with clients’ production goals, ensuring seamless integration with existing extrusion lines.

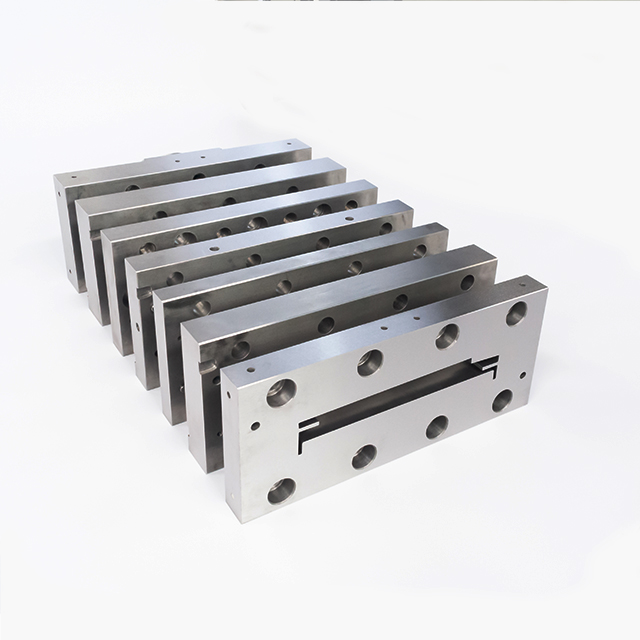

As a manufacturer based in China, JINTU MOULD benefits from access to cutting-edge materials and a skilled workforce. The brand uses premium-grade tool steels and advanced heat treatment processes to craft molds that withstand the rigors of high-volume production while maintaining dimensional accuracy. This commitment to quality ensures that JINTU MOULD’s molds deliver consistent results, minimizing downtime and maximizing productivity for clients.

JINTU MOULD’s WPC hollow board extrusion molds are equally impressive, designed to produce boards with uniform hollow structures that enhance stiffness and reduce weight. These molds are perfect for applications such as fencing, cladding, and interior partitions, where lightweight yet strong materials are essential. The brand’s expertise in mold flow analysis guarantees optimal material distribution, preventing defects like warping or uneven surfaces.

For businesses seeking to differentiate their products, JINTU MOULD offers a range of customization options. From embossed wood grain textures to co-extruded layers for enhanced UV resistance, the brand’s molds enable clients to create WPC products that stand out in a competitive market. JINTU MOULD also provides prototyping services, allowing clients to test and refine their designs before full-scale production.

In addition to technical excellence, JINTU MOULD prioritizes customer satisfaction. The brand’s team of engineers and technicians offers comprehensive support, from mold installation and commissioning to ongoing maintenance and troubleshooting. This hands-on approach ensures that clients can maximize the lifespan of their molds and achieve optimal production efficiency.

JINTU MOULD’s commitment to sustainability further enhances its appeal. The brand’s molds are designed to minimize material waste and energy consumption during production, aligning with global trends toward eco-friendly manufacturing. By choosing JINTU MOULD, businesses not only invest in high-performance tools but also contribute to a greener future.

In a market saturated with generic solutions, JINTU MOULD stands out as a partner that understands the nuances of WPC extrusion. Whether you’re a seasoned manufacturer or a new entrant to the composite materials industry, JINTU MOULD’s custom molds and expert support ensure that your production goals are met with precision and innovation.

In conclusion, JINTU MOULD is more than just a mold manufacturer—it’s a strategic ally for businesses seeking to excel in the WPC sector. With its focus on customization, quality, and sustainability, JINTU MOULD is poised to drive the next wave of innovation in hollow decking and board extrusion.