JINTU MOULD Composite Molds

In the modern construction and outdoor building materials industry, WPC (Wood-Plastic Composite) products have gained widespread popularity due to their durability, environmental friendliness, and aesthetic appeal. As demand for WPC composite beams, columns, and posts continues to rise, so does the need for high-quality WPC composite beam extrusion mold and plastic co-extrusion die for composite column solutions. At the forefront of this growing market is JINTU MOULD, a leading WPC extrusion mold manufacturer in China, known for delivering precision-engineered, custom tooling systems that meet global standards.

The Role of Extrusion Molds in WPC Production

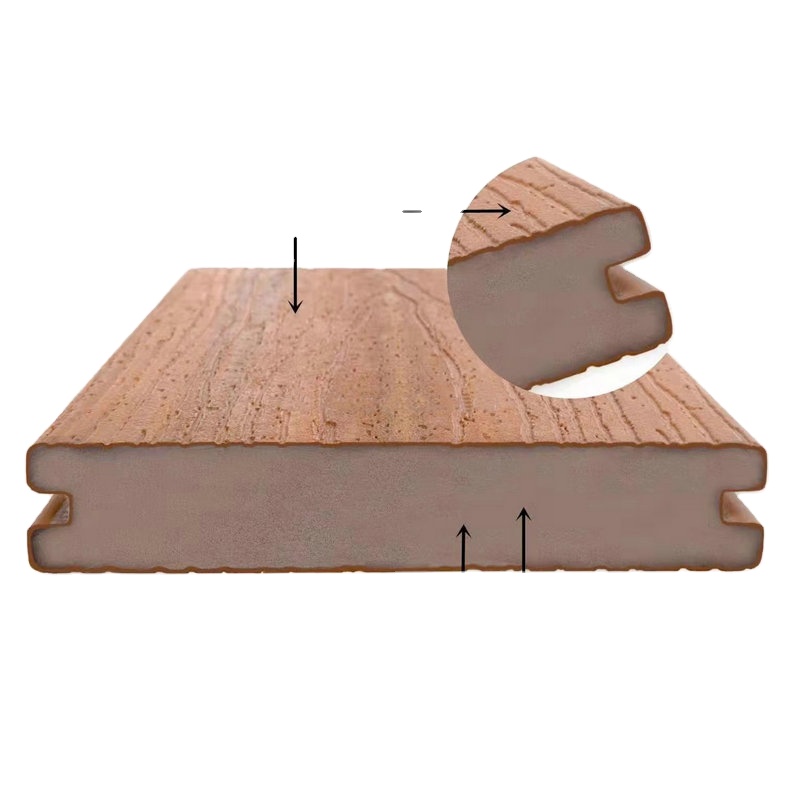

The foundation of any successful WPC manufacturing process lies in the quality of its extrusion mold. These molds determine the final shape, texture, and structural integrity of composite beams, columns, and posts. Whether it's for residential decking, commercial architecture, or urban infrastructure, the mold must ensure consistent output, dimensional accuracy, and surface finish.

Co-extrusion dies, particularly those used in producing composite columns, allow manufacturers to apply protective or decorative outer layers during the extrusion process. This not only enhances the product’s weather resistance and UV protection but also improves its visual appeal — all without compromising structural performance.

Why Choose JINTU MOULD?

As a trusted WPC extrusion mold manufacturer, JINTU MOULD has built a strong reputation for innovation, reliability, and customer-focused service. Based in China, the company combines advanced engineering expertise with state-of-the-art manufacturing facilities to provide tailored tooling solutions for clients around the world.

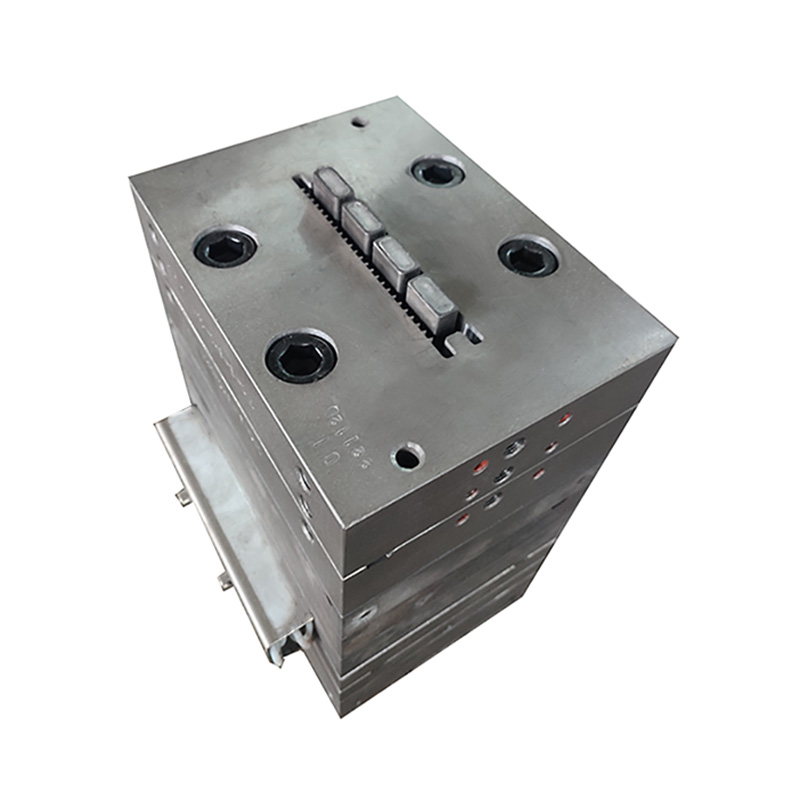

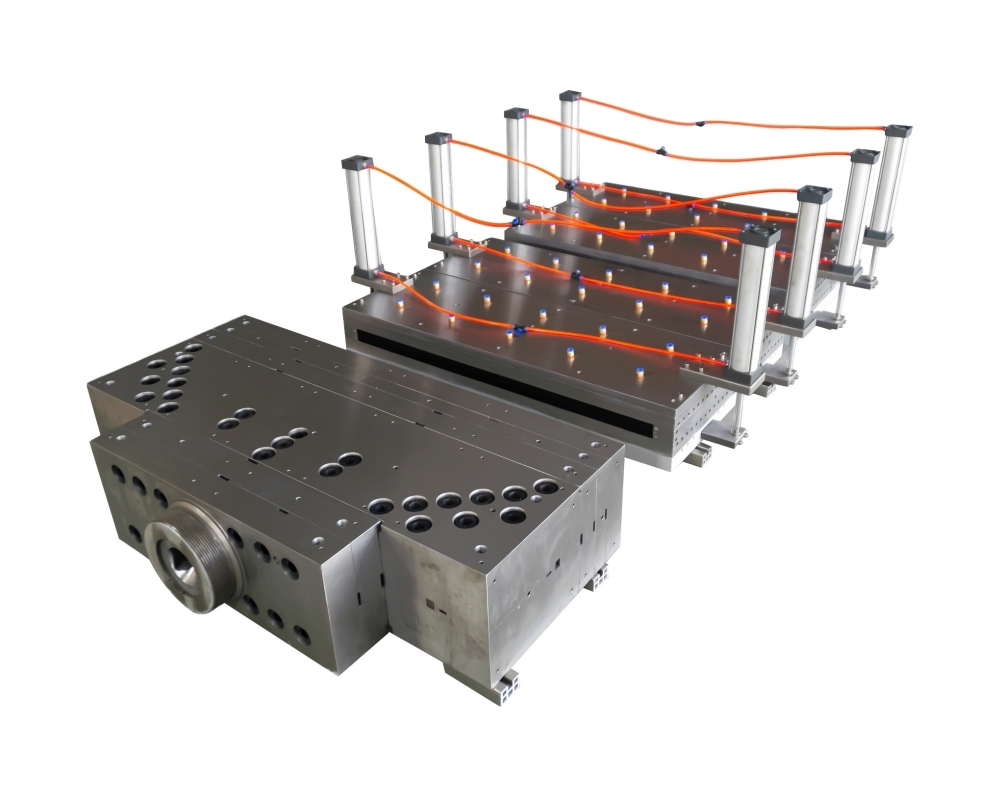

What sets JINTU MOULD apart is its deep understanding of both material behavior and production requirements. Their team of experienced engineers works closely with clients to design and produce custom composite post extrusion tools that match specific product profiles, output volumes, and machinery setups. Whether you're looking for single-layer extrusion molds or complex co-extrusion systems, JINTU MOULD delivers precision-crafted solutions that maximize efficiency and minimize downtime.

Full Customization for Diverse Applications

One of the key advantages of working with JINTU MOULD is its ability to offer custom extrusion tooling tailored to your unique needs. From intricate architectural profiles to industrial-grade support beams, JINTU MOULD ensures that every mold meets exact specifications.

This customization extends beyond shape and size. Clients can choose from a range of internal cooling structures, flow channel designs, and surface textures to achieve optimal extrusion performance and finish. Additionally, JINTU MOULD supports various WPC formulations, including wood fiber-based and bamboo-based composites, ensuring compatibility across different raw material sources.

For large-scale producers and startup manufacturers alike, this level of flexibility allows for greater creativity and adaptability in product development. Whether you're entering a new market or expanding your current line, JINTU MOULD helps bring your vision to life with reliable, high-performance tooling.

High-Quality Manufacturing Standards

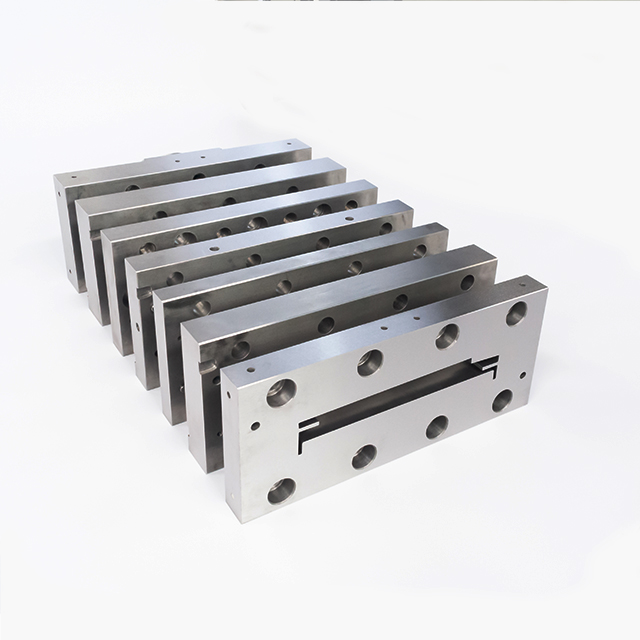

As a China-based manufacturer, JINTU MOULD adheres strictly to international quality control protocols. All molds are precision-machined using CNC lathes, EDM, and 3D laser scanning technologies to ensure tight tolerances and long-term durability. Each mold undergoes rigorous testing before delivery to guarantee smooth extrusion, minimal wear, and consistent output over time.

Furthermore, JINTU MOULD is committed to sustainable practices by optimizing mold lifecycles and reducing material waste during production. This approach not only benefits the environment but also lowers the total cost of ownership for end users.

Global Reach with Local Support

While based in China, JINTU MOULD serves a diverse clientele across Asia, Europe, North America, and Australia. The company offers comprehensive after-sales support, including technical guidance, maintenance training, and spare parts supply, ensuring that clients receive continuous assistance throughout the mold’s lifecycle.

Additionally, JINTU MOULD provides full documentation, including CAD drawings, assembly instructions, and troubleshooting guides, making integration into existing production lines seamless and efficient.

For businesses seeking top-tier WPC composite beam extrusion mold and plastic co-extrusion die for composite column, JINTU MOULD stands out as a premier custom composite post extrusion tool supplier. With a strong focus on innovation, precision, and sustainability, JINTU MOULD delivers tailor-made tooling solutions that empower WPC manufacturers worldwide.

As a China-based WPC extrusion mold manufacturer, JINTU MOULD continues to lead the way in developing advanced, durable, and highly efficient molds that meet evolving industry demands. Whether you're producing decorative columns or structural beams, JINTU MOULD is your trusted partner in achieving excellence in WPC extrusion.